Mobile cable rewinding machine with printing system – MORA 10

Purpose and possible applications

Purpose and possible applications

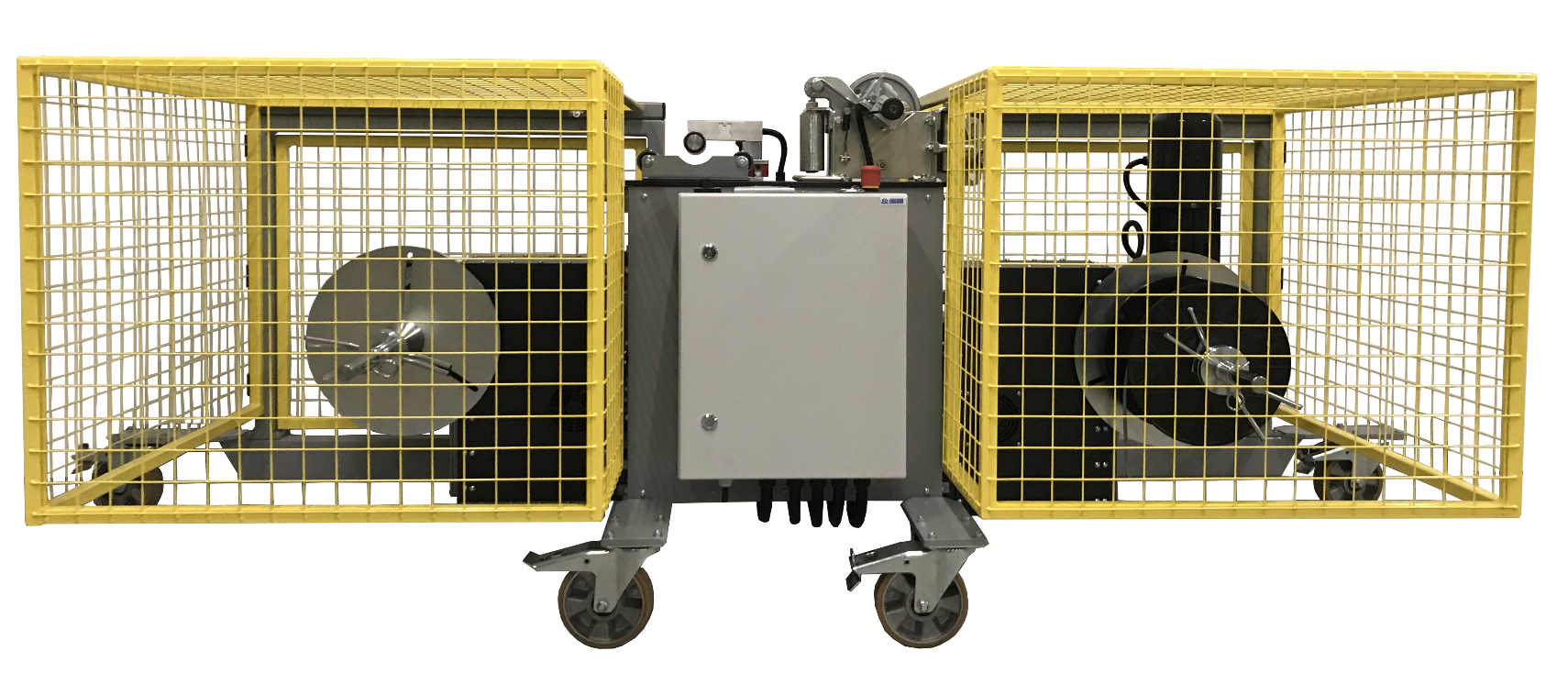

The mobile, compact device, equipped with support wheels and designed for rewinding of cables and electrical or optical wires, as well as other similar materials from one cable drum to another, weighing up to 150 kg. The device enables operation with programming of the specified cable length and it is adapted to work with the printer EBS-6100, which allows you to perform an overprint on the cable when rewinding. Due to implementation of highly advanced automation solutions in the control system, the winding machine has the ability to wind cables on special cable drums with a conical core, which allows for unwinding the cable without the need of using a feeder.

In the device, there is applied an electronic synchronization of the rotary motion during cable winding with bidirectional linear movement of the cable being laid. Thanks to synchronization of the device working movements, the use of overload protection systems and advanced automation used for control, this device allows to wind cables and wires without use of human hand force and the need of constant and direct supervision. A characteristic feature of the device is a simple, intuitive operation and compact and stable construction, making it very durable and reliable. It significantly reduces the human workload and improves safety and health conditions at work. Construction and principle of operation The device structure equipped with support wheels, made of welded steel sections and powder painted in RAL 5017. All the operating movements of the device are mechanized, which allows you to work without the use of human hand force. The winding machine consists of three main functional units: the unwinding unit with a brake, the winding unit with a motor and the main body with control cabinet and counting device. The unwinding and winding units perform linear, bidirectional, horizontal and vertical movements. Those movements are used for loading and unloading of the cable drums and are controlled by the buttons on the control panel of the machine. Besides, the winding unit, during the operation of the winding machine, performs linear horizontal and bidirectional movement within the limits set by the special laser pointer identifying the width of the cable drum. The linear speed of this movement is synchronized with the rotational speed of a bearing shaft in the winding unit and enables precise cable rewinding one coil next to another. The cable winding and travel of the winding unit during cable laying are effected with the use of stepper motors controlled by electronic controllers with overload protection. Those controllers communicate with each other by means of a microprocessor, which synchronizes the rotational movement of the bearing shaft in the winding unit with the linear horizontal movement performed by the body of the winding unit within the limits set by means of interlocks. . Technical data empty weight of the winding machine: ~0.40 t Related documents Operation and maintenance manual. Manufacturer's warranty The device is covered by the 12 month warranty for correct operation, with the exception of parts subject to natural wear and tear during normal use. MORA 10 with PLC control system. the operation program of the winding machine allows to wind cables on special spools with conical cores that allow quick unwinding of the material without the use of additional equipment such as the cable feeder.

MORA 10 - mobile winding machine for cables in drums up to 150kg

More

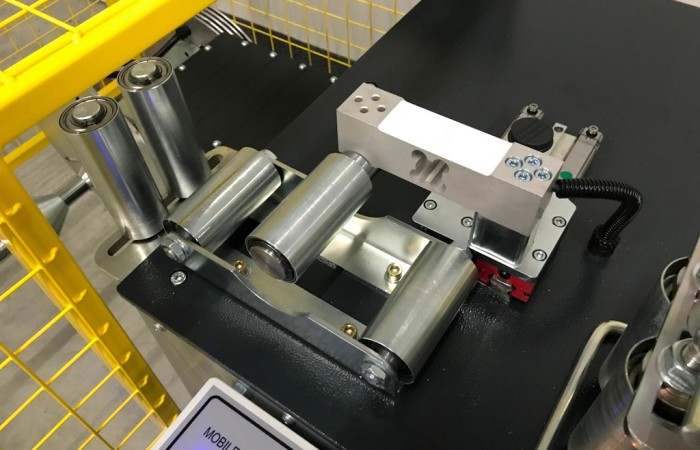

The electronic programmer enables to enter the outer diameter of the rewound cable, and then the rotational speed for cable rewinding is set by means of a potentiometer. The cable laying device moves at the speed proportional to the rewinding speed, defined previously by entered value of cable diameter. Such a solution ensures high accuracy in laying of the cable on the drum while rewinding. The other drives are realized using induction electric motors integrated with bevel gears. The device is equipped with an electronic counter and a programmer which enables programming of rewinding to the desired length. In the event of completion of rewinding process, overload or failure of the machine, the automatic control will stop the device. The main body is made with welded steel hollow sections. The control cabinet with control panel is attached to the main body. The control panel includes all the control elements of the machine, the counter and the length programmer. Two guide roller assemblies for guiding a cable, the device for length measurement and a rack for mounting a print head are placed on the table. On the main body, next to the control cabinet, there is a place provided for suspension of the printing machine EBS-6100.

NOTICE! - the operation program of the winding machine allows to wind cables on special spools with conical cores that allow quick unwinding of the material without the use of additional equipment such as the cable feeder.

The applied electrical overload protectors, the advanced control system, the compact and stable mechanical structure, powder coatings and high quality workmanship ensure long-term use in production conditions.

dimensions (width/height/length): 1300/1200/2300 mm

power supply: 3x400 V / 50 Hz / 6 A

lifting capacity of the unwinding unit: max. 0.15 t

lifting capacity of the winding unit: max. 0.15 t

winding speed: 0-150 rpm

linear speed of cable laying: 0-30 mm/s

diameter of the cable drum: max. ø 900 mm

width of the cable drum: max. 500 mm

axial hole of the cable drum: ø 30-50 mm

power of rewinding motor: 1,1 kW

power of horizontal travel motors: 0,12 kW

power of lifting motors: 0,25 kW

installed power: 2,0 kW

protection class: IP 54

noise emission: max. 75 dB

counting device enabling length programming

static brake, manually adjusted

electromagnetic brake, automatic

EC declaration of conformity (CE mark).

Certificate of quality of welded joints.

Certificate of effectiveness of neutral earthing.Film