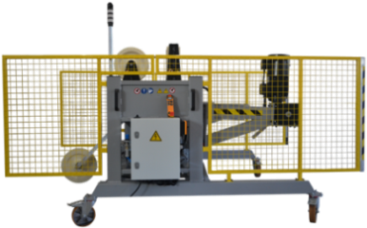

Feeder for cables on large drums - up to 1T. Cables 4-30mm O.D. - MORA 15

Purpose and aplication

A mobile free-standing device, the task of which is to unwind cables and wires, electric and fiber optic, with increased external diameters, which are stored on large and heavy drums. Thanks to the use of a pneumatic control arm, it is possible to adjust the tension of the supplied cable. The speed of unwinding the cable is regulated automatically, depending on the deflection of the control arm. The device is equipped with an electro-hydraulic system for crimping and lifting the drums, allowing for loading and unloading heavy cable drums without having to lift them manually. Movements of the squeezing and lifting arms are performed from the position of the wireless remote control. The device can work as unrolling the cables fed into the cutting machines or winders. Cable unwound with an electric motor - no pulling force !!!

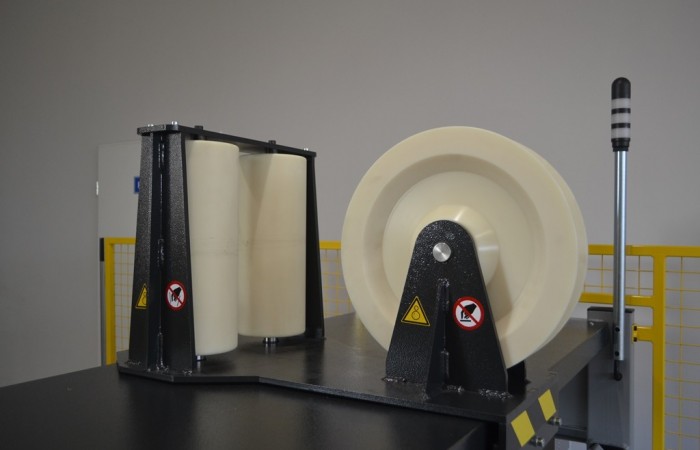

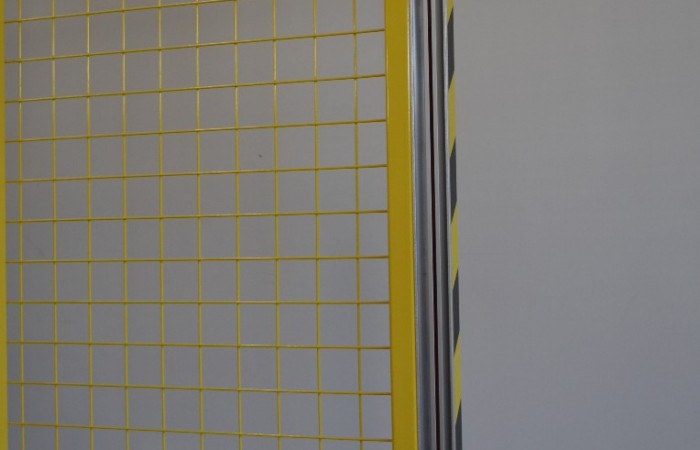

Construction and principle of operation Welded construction of thick-walled steel profiles, powder coated RAL 7035 + RAL 7021 graphite additives. The supporting frame is mounted on four swivel wheels, with high load capacity, with a mechanical lock function. On the main frame, is mounted hydraulic unit, which, together with the electro-manifolds and other hydraulic components, is responsible for the movements of the arms clamping and lifting cable drums. The cable drum clamping unit is designed as a two-arm claw gripper which axially clamps the drums into centering cones on both sides. The third hydraulic cylinder serves to lift the cable drum clamped with centering cones. The drive for clamping and lifting the cable reel is controlled from the position of the remote control or the machine's main panel. The system of crimping the drums is equipped with a module securing their excessive compression, which protects the drums from possible damage. The cable unwinding module is an electric induction motor which transfers the drive to the drive shaft by means of an angular reducer. Next, with the use of a flexible "carrier", on the drum from which the cable will be unwound. The motor is controlled by a frequency converter, a magnetic piston position sensor in the pneumatic actuator in the control arm. The pneumatic control arm ends with a large-diameter guide wheel. Depending on the position of the arm, it starts or stops the cable unwinding drive, and also continuously adjusts the rotational speed of the drum. The higher the position of the arm, the slower the unwinding speed is and the extreme the machine stops. When the control arm is lowered, the cable unwinding drive is engaged and the rotational speed is increased until the arm angle stabilizes. The drum rotation zone is fenced off with yellow steel covers and from the drum loading side, the zone is protected by optical infrared barriers. In the event of cable termination on the unwound spool, completion of the unwinding process, overload or machine failure, the automatic control stops the device (also the winding machine, automatic cutting machine, etc. ) and optically signals the completion of work or a failure. The applied electrical overload protection, compact and stable mechanical structure, powder coatings and high-quality workmanship ensure long-term use in production conditions. Technical data Functions Related documents Warranty conditions The device is covered by the 12-month warranty period, with the exception of part subject to natural wear and tear during normal use.More

MOBILE CABLE PREFEEDING MACHINE MORA 15 (CABLE DRUMS UP TO 1000 KG)

SPECIFICATION GROUP

ITEM

DESCRIPTION

Technical data

Power supply

3x400 VAC 16A

Unwinding motor

Induction motor 4.0 kW/400VAC

Protection barriers

The MORA 15 unwinder is equipped with metal barriers separating the surface of the rotating drum. Optical barriers on the loading side of the drum, automatically switched on when the cable rewinding process starts. Violation of the optical barrier signal causes the process of rewinding the cable to be stopped.

Construction data

Mobile support structure

Support frame welded of steel profiles, powder coated. The whole machine rests on 4 supporting wheels allowing easy movement of the machine within the production hall - wheels with a mechanical lock for operation - the machine does no requires foundation in the floor.

Empty weight

~600kg

Range of drum diemeters

Ø600 - 1600mm

Range of drum width

400 - 950mm

Max. drum weight

1000kg

Range of cable outer diameter

Ø4mm - Ø30mm

Max. drum rotational speed

84 rpm - autimatyc adjustment by the buffering arm

Cable prefeeding process

The machine's task is to unwind cables from drums. The drums are not pulled by the cable. The drive is an electric motor, the revolutions of which are regulated automatically within the operating range of the drive by the control arm.

Clamping and lifting of drums module

The mechanism of clamping and lifting cable drums is based on the interaction of power electrohydraulics. All movements of the arms lifting / clamping the drums are realized from the main control panel of the machine and buttons on the remote control. Elements gripping the drums consist of two sliding arms clamping the spools into centering cones on both sides.

Centering the drum

Before being lifted up, the cable reels are clamped with an electro-hydraulic system into centering cones made of high-quality steel. Cones guide the spools in the range of axial holes: from Ø60 - Ø120 mm.

Winding motor rotation switch

In emergency situations or after working with the cable, it is possible to change the rotation of the cable unwinding motor. This function allows the end of the cable to be wound on the drum to protect it.

Safety systems

Optical indication of the machine operating states

The cable unwining machine MORA 15 is equipped with a three-color LED lamp, signaling the status of the device. Green - normal operation mode; Orange - static mode; Red - emergency condition.

Electric overload

In case of machine overload, the electronic control system of the device stops the rewinding process and indicates the emergency state by the red flashlight.

Cable detection system

The end of the cable on the drum is associated with the lowering of the control arm, which causes an alarm and the machine stops.

Cable tension pneumatic mechanism

The pneumatic control arm is suspended from a pneumatic cylinder. It is possible to regulate the pressure in the actuator, which influences the tension of the unwound cable.

Optional accessories

PLC controller + cable tension sensor

Equipping the machine with a strain gauge allows you to view the cable's tension in Newtons. The sensor is mounted on one of the rollers of the arm controlling the speed of unwinding the cable. The PLC menu allows programming the maximum tension force, the so-called critical force, beyond which the cable rewinding process is stopped - the feeder and winding machine are stopped.Cable tension adjusted manually with a knob on the pneumatic reducer.

Automatic cable tension adjustment

It is possible to equip the module with a tension sensor with a proportional valve, whose task is to automatically adjust the pressure in the pneumatic cylinder, according to the programmed tension force when unwinding the cable.