Free-standing winding/rewinding machine for cables with small cross sections - MORA 7

Scope of application

Scope of application

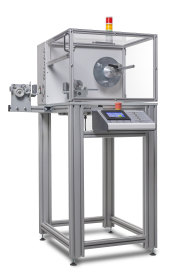

A series of compact, free-standing devices, intended to wind or rewind cables and electrical, optical wires or other similar materials with small outer diameters. Cables are taken from reels or conical containers and wound onto plastic or cardboard drums. The use of a non-reel coiler enables Winding cables into coils. An enhanced control module allows for, among others, storing the operating programs with full configuration and programming of cable length.

More

Owing to the use of cable laying device synchronized with rotational motion of the bearing shaft, overload protection and an advanced automation control unit, it is possible to rewind cables and wires without the need of continuous, direct supervision. The device is characterized by a simple, intuitive operation and a compact and stable structure, making it very durable and reliable.

Construction and principle of operation

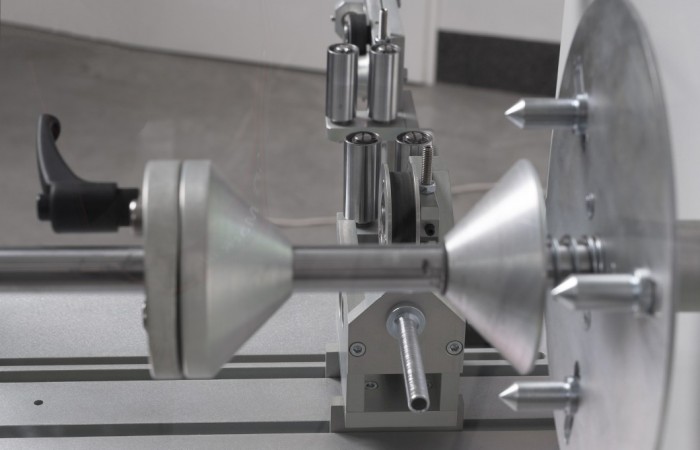

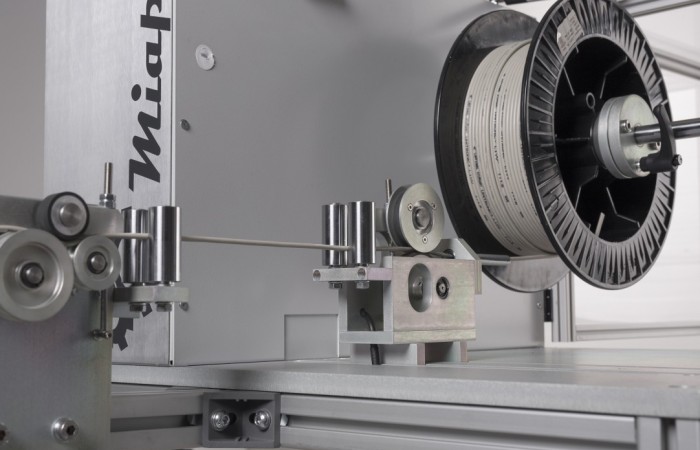

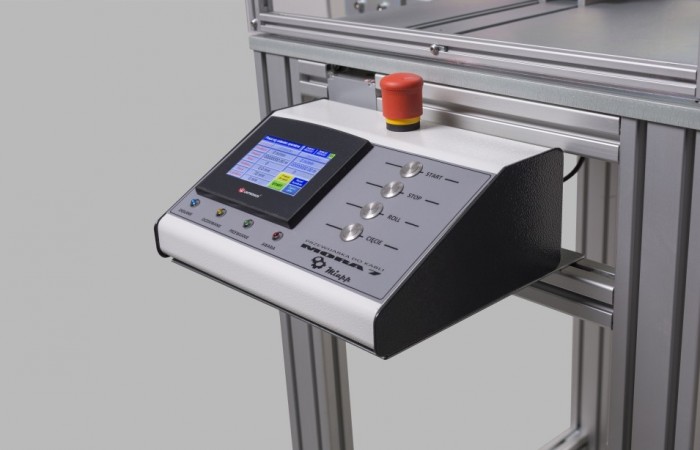

The frame structure made of aluminum profiles, the body made of steel sheet, powder coated in RAL colors. The Winding unit is equipped with an electric induction motor which transmits the drive to the driving plate and further by means of flexible pins, to a reel where cable is wound. The motor is controlled from the operator panel, through a frequency inverter, supported by a microprocessor based PLC. The frequency inverter provides motor overload protection. The controller allows for programming all the machine settings, including program edition in memory of the device. Automatic cable laying device with length measurement is composed of a trolley and a measuring wheel moving in parallel to the drum axes. The device is driven by a stepper motor via a top rated toothed belt. The laying device performs bidirectional, linear movement, within the drum width limits programmed in the menu. The motor of cable laying device is also controlled via microprocessor-based PLC that besides overload protection, ensures smooth setting of linear speed synchronized with rotational speed of rewound cable, depending on its outer diameter. PLC acts as a counter and a programmer that allows us to set a reference rewinding length. If the unwinding reel is running out of cable, or the rewinding process stops, or the machine is overloaded and fails, then the automation control unit stops the device and indicates visually the operation stop or failure. The delivery module of the device (MORA 7.2) is designed as a bearing shaft hung unilaterally on, aluminium profiles. The shaft is equipped with a quick-locking system that couples the shaft with a drum and an electromagnetic static brake as well as a dynamic one – braking force of unwound reel is controlled from the main panel of the machine. The applied electrical overload protection, simple and stable mechanical structure, powder coatings and high quality workmanship ensure long-term use in production conditions.

Technical data

| MORA SERIES 7 | MORA 7.1 (winding machine) | MORA 7.2 (rewinding machine) |

| Power supply | 230VAC 10A | |

| Installed power | 0,7kW | |

| Winding device motor | 0,4kW/230VAC | |

| Cable laying device motor | stepper motor, bipolar 6,3Nm | |

| Empty weight | ~90kg | ~110kg |

| Overall dimensions | 670/760/1430mm | 750/760/1430mm |

| Max. reel diameter - winding | ø300mm | |

| Max. reel diameter - unwinding | - | ø400mm |

| Max. reel width | 350mm | |

| Max. reel weight | 1 x 10kg | 2 x 10kg |

| Max. external cable diameter | ø8mm | |

| Max. rotational speed | 0 - 290rpm | 140rpm |

| Cable laying device | automatic, synchronized with shaft rotation | |

| Rewinding unit with electromagnetic brake | - | + |

| Control system | PLC, storage of operating modes and length programming | |

| Working brake | - | + |

| Service brake | - | + |

| Working temperature | 5-35 ̊C | |

Related documents

- Operation and maintenance manual PL/EN

- Declaration od conformity (CE mark)

- Quality certificate of earthing efficiency

- Meter calibration certificate

Manufacturer's warranty

The device is covered with 12-mont warranty for proper operation.

Film

MORA 7 - cable rewinding machine with PLC control system !!!

MORA 7 - rolling in skeins

MORA 7 - 24.01.2013r.

MORA 7 - cable rewinding machine with small sections

MORA 7- test for client